Glass wool is known as fiberglass insulation. It was invented in 1933 by Games Slayter while he worked at Owens Glass (now known as Owens Corning).

It is manufactured by combining sand and recycled glass at a temperature of 1,450 degrees celsius. The glass that is produced is converted into fibers with a method similar to making cotton candy.

How safe is blown-in and batt fiberglass insulation?

It is a material that can irritate eyes, skin, and lungs. It is relatively good at resisting mold. However pests enjoy nesting and living in fiberglass. We do a lot of insulation removal in attics where rats made a mess.

Why use fiberglass insulation in your Austin TX area building?

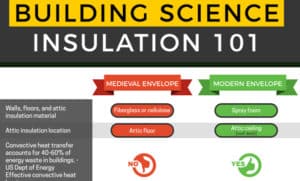

Fiberglass attic insulation service in Austin is great when your most important decision making factor is price of installation. Fiberglass is cheap. However, fiberglass insulation will cost you significantly more in the long run. So I would not advise someone to install fiberglass if they plan to own and pay the utility bills on a building for more than 3-years. If you are investing in the long term value of your building, then spray foam is a better solution.

Which fiberglass insulation application method is right for your Austin project?

Fiberglass Insulation Batts

Typically known as “the pink stuff”, rolls of fiberglass (batts) have been widely used in production (cookie cutter) home building. It is the cheapest option for a builder when there is not much concern much about the performance of the home. While builders install fiberglass, you will rarely find a builder choosing to put fiberglass in their own home.

BIBS & Blown-In Fiberglass Insulation

This method of using fiberglass is better than batts because it can fill around pipes, wires, and in smaller corners. Blown fiberglass costs more to install than batts because of the insulation blowing truck needed. Blowing fiberglass does settle, but it overcomes the gaps and cracks issue present with batts. The two main manufacturers of blown fiberglass are Johns Manville and Owens Corning.

Where to buy fiberglass insulation? How much does it cost?

Of course you can go to your nearest Lowes, Home Depot or other Building Supply store. You can buy it, rent the equipment to install it, and then spend time and money having it installed.

However, with a insulation contractor like Stellrr, you can get the product purchased and installed for about the same price you would pay just to buy it from a local Austin building supply store like Lowes.

That’s right, there is no need to pay for the product, pay for the equipment rental, and pay laborers to install it. Instead you can get it all done for you for about the price of materials. Of course there are exceptions to this rule, like having a super small job may mean that the contractor has to charge a minimum to come out, but you will never know until you ask them.

What is the R-value of Fiberglass?

While the R-value varies from different manufacturers and application methods, here are some guidelines. Fiberglass batt rolls are generally R-2.7 to R-3.8 per inch. On the other hand, loose blown fiberglass ranges from R-2.2 to R-2.9 per inch.

How much fiberglass insulation do I need in Austin TX?

The building codes in Texas follow the 2015 IECC and the City of Austin in many cases requires even more insulation. Here is a breakdown:

- Texas Walls: R-13

- Austin Walls: R19, 15+2, 13+3

- Texas & Austin Floors: R-13

- Texas & Austin Attic: R38 (unless it is spray foam on the roof deck, which is R25 in Austin)

Here is an example: Let’s say you have an existing home that has 7.5-inches of blown fiberglass in the attic. Let’s say the R-value is 2.5 per inch as a guesstimate. So 7.5-inches x 2.5 per inch is: R-19 currently in your attic. You need a minimum of R-38 to meet code requirements. Meaning you need to add R-19 or double your insulation in the attic.

Now to calculate the number of bags of fiberglass needed to be blown in. According to the manufacturers, a bag of fiberglass blown at R19, will cover about 100 sq ft. So if you have a single story 2,400 sq ft home, you will need 24 bags. You need a bag for every 100 sq ft to blow at R19. And if you were blowing a structure with no insulation in the attic, you would need 1 bag for every 50 sq ft.

How to install fiberglass insulation?

There is a lot to installing fiberglass insulation, and the primary training organization is the NIA National Insulation Association. You can get a taste of what to do on their website. People invest years in learning the best techniques to install fiberglass, as well as invest $80,000 to $120,000 in the proper equipment for a rig that allows them to do the job right, fast, and efficiently. More often than not, after reading about the complications of proper fiberglass insulation system installation, you’ll be looking for a good insulation contractor.

When to install fiberglass?

New Construction

In this case, your prospective contractor will want the blueprints early on so they can provide an initial estimate. After you have the building framed, they should go out and adjust their bid to the actual project specs, accounting for any changes or unreadable items on the blueprint. Once your pre-drywall inspections are done, it is time to insulate.

Retrofit (Existing Homes, Remodels)

When you are needing fiberglass added to or replaced, you have a few options. One, for your attic, that can typically be blown in anytime you are ready. You will want to consider removing the old insulation, and having the attic air-sealed prior to installation so that you maximize energy efficiency. Now if you are wanting your walls insulated without removing sheetrock or siding, that can be done. The installer will drill and cover up small holes between the studs to install the fiberglass. If you have siding, the installer can remove the strip of siding, drill into the plywood, install insulation, plug the hole, and re-apply the siding. It will look like nothing happened. But before having insulation installed, be sure to get a Building Energy Performance Diagnostic Audit because something else may be the real problem.

Exposed (Metal Buildings, Unfinished Structures)

Insulating a exposed structure with fiberglass is an option, although if you plan to leave it exposed, then closed-cell spray foam in Austin TX is a much better solution because of the density and rigidity of the material. If you are not planning to close in the structure, then as soon as it is water tight, and your plumbing, electrical, and HVAC are done, you can have fiberglass installed.

What does fiberglass insulation cost in Austin TX?

Check out my FREE guide on that reveals what Austin area people paid for fiberglass and average cost categorized by project type.

Here is what to do next:

Call 512-520-0044 today! Claim your Home Energy Audit, Thermal Mapping, and Blower Door Test ($297 Value FREE). Or download our e-book: Secrets to Making Your Home Comfortable & Energy Efficient! So you can make an informed and intelligent decision when hiring an air duct insulation contractor near me!